List of Persons Employed at Boston Navy Yard 1846

by John G. M. Sharp

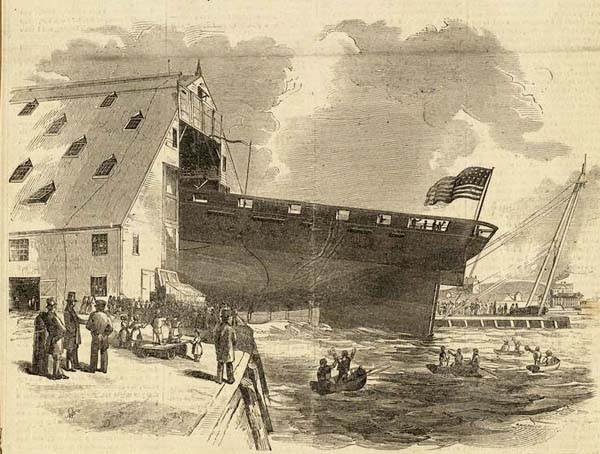

Launch of the USS Princeton, circa 1852

Introduction: From its rough beginning in 1801, the Charleston Navy Yard, aka Boston Navy Yard, civilian workers had often outnumbered military personnel and performed the greatest share of the actual labor. Naval officers assigned to Boston typically served two and three year tours, while the majority of the civilian workplace remained at Yard throughout their adult lives. The following is a transcribed list of the names, occupations, annual and per diem pay rates and duties assigned to the employees who worked at the Boston Navy Yard in 1846. This list was compiled and forwarded by Commodore Foxhall Alexander Parker, the commandant of the Boston Navy Yard, at the direction of Secretary of the Navy, George Bancroft, on 6 January 1846.1 The list transcribed below was Commodore Parker’s answer to Bancroft’s queries regarding the number of shipyard employees, their occupations, their specific duties and their respective salary or wage. This 1846 Employee List is important since information therein allows modern historians and scholars to closely study the economic and social relationship of a fascinating and bygone era. The exceptional preservation and survival of this list is a direct consequence of the document being filed with the papers of the Secretary of the Navy.

1. Parker to Bancroft 6 January 1846, pp. 1-11, Letters Received by the Secretary of the Navy from Captains (“Captains Letters”), Volume 326, 1 Jan 1846 to 31 Jan 1846, Letter Number 26, RG 260, National Archives and Records Administration, Washington, D.C.

Commanding Boston Navy Yard in 1846 was the Commandant, Commodore Foxhall Alexander Parker Sr., 1788-1857), who had assumed command on 28 November 1845 and remained until December 1848. Commodore Parker was a native of Virginia who had joined the Navy as a midshipman on January 1, 1808. During the War of 1812 Parker was captured at sea. He was commissioned lieutenant on March 9, 1813, commander on March 3, 1825, and captain on March 3, 1835. He received orders to take Brandywine and sloop-of-war St. Louis to China, where U.S. Diplomat Caleb Cushing was to negotiate a commercial treaty. The parties signed the Treaty of Wanghia on July 3, 1844. Brandywine arrived back in the U.S. in 1846, and Commodore Parker received a gift of a silver plate from the American merchants in China for his efforts on their behalf. He then came ashore to command the Boston Navy Yard until 1849. Parker’s career ended on September 13, 1855, when he was placed on the reserve list in the navy’s service-wide effort to reduce the number of senior officers and improve the chances of promotion for their juniors. He died a little more than two years later on November 23, 1857 at Philadelphia, Pennsylvania.2

2.“Foxhall Alexander Parker Sr”, USS Constitution Museum https://ussconstitutionmuseum.org/crew/foxhall-alexander-parker-sr/

Samuel Moore Pook (August 15, 1804 to December 2, 1878), a renowned architect and engineer, served as the shipyard naval constructor. In 1866, Naval Constructors gained the rank and recognition previously available to doctors of the Medical Corps and pursers of the Supply Corps. Pook was a noted clipper ship naval architect; in 1843 he was appointed to serve as the Boston Navy Yard technical and engineering expert. Pook, who was born in Boston, had been educated in the local public schools, was intelligent and hardworking. He would prepare the designs for many of the new vessels constructed or refitted at the shipyard throughout the next three decades. He was the highest paid individual $2,300 per annum) listed below.

Samuel Moor Pook, Naval ConstructorThe number of mechanics and laborers at the Boston shipyard during the first half of the 1840s had generally increased. For example the yard employed 541 men on April 1842 and 623 on October 1843. The 6 January 1846 list of employees forwarded to Secretary Bancroft enumerated 314 civilian employees. This relatively low number reflected the reduced winter workload due to severe snow and ice. The advent of the Mexican-American War, sparked the Navy Department to give orders to the Boston Navy Yard to expand the number of employees to expedite repair of USS Princeton, United States, Independence and the Ohio. By 1 July 1846 the numbers of civilian employees stood at a decade long high of 818 employees.3 Additional work space had to be provided in the plumber's shop and more than ordinary repairs were made to the furnaces at the Ropewalk and engine shops.

3. Frederic R. Black and Edwin C. Bearss Charlestown Navy Yard 1842-1890 (National Park Service, Washington, D.C., 1993), p. 199.

The volume of work activity at Boston Navy Yard increased dramatically between the summer of 1845 and spring of 1848. During the antebellum era, the Boston Naval Yard was significant as the site of one of the first two naval dry docks in the United States, which allowed it to work on ten ships that took part in the Mexican-American war or participated in the blockade of Veracruz as support vessel. Immediately following the declaration of war by the United States on May 13, 1846, the Secretary of the Navy authorized all Navy Yard commandants to hire more workmen to meet the needs of the emergency.

The constant demand on the Boston barracks for personnel as Marine guards on ship and for duty in Mexico compelled the navy yard commandant to make increasing use of civilian watchmen to provide for yard security Taking advantage of the situation, the watchmen petitioned for an increase in pay in the spring of 1846. They pointed out that their wages were $12 per month and rations while watchmen at Portsmouth were paid $28 per month and those at New York $1.25 per day. Commandant Parker forwarded the petition and urged that it be granted because it was impossible to obtain good men at the wages allowed. The bureau concurred and authorized the watchmen to be paid $1.00 per day.4

4. Frederic R. Black and Edwin C. Bearss, Ibid, pp. 35-60.

As Navy Yard Commandant, Commodore Parker’s word was law. However, while the position of commanding officer gave him near absolute authority, the directives of the Department of the Navy and recently created bureau system placed significant restrains on his discretion to create and fill jobs. Working closely with Parker was his able executive officer Captain Andrew Hull Foote. For continuity, civilian workers looked to their Master Mechanics and the Chief Clerks for work direction. These individuals provided the essential leadership stability amidst an ever changing military management cadre. Military/civilian relations reflect the hierarchal nature of both the shipyard and the larger society. Civilian workers had only limited, if any, social interaction with officers. Naval officers who had spent large parts of their careers at sea often found civilian concerns puzzling. Likewise, naval officers who were used to instant obedience often chafed at having to explain actions to their civilian subordinates. For many civilians, day to day relations remained cordial but distant. At times politics and economics created friction between the two groups, especially the imposition of political patronage and worker demands for higher pay and job security.

At the apex of shipyard civilian employment were the appointed clerks. These individuals owed their appointments either to relationships or at the behest of powerful politicians. Many of the 1846 clerks were similar to modern administrative officers and exercised considerable authority within their domain. They enjoyed relative job security with fixed annual salaries, unlike the mechanics and tradesman who were paid wages on daily or per diem basis. Some of these new clerk jobs though had neither security nor annual salary. These new jobs labeled “writer” were solely clerical. Their requisite qualifications were accurate, neat and rapid penmanship. Such per diem writer jobs quickly proliferated within the new Bureau system.

In 1846 the United States Navy was moving toward steam vessels, and the 1846 Employee List reflects this trend. Nevertheless the shipyard retained a strong contingent of traditional nautical trades, such as ship carpenters and sailmakers. The sailmakers were led by master sailmaker Joseph F. Boyd, while the carpenters were led by carpenter foreman Nathaniel Croker. Master ship joiner Alexander McFarlane directed joiners who repaired the numerous vessels for overhaul or routine maintenance Transportation on the shipyard in 1846 remained the province of horses and oxen. Laborer Francis Powers was in charge of “bedding down & feeding the Horses & Oxen” while blacksmith John McCumber took care of “shoeing the horses and oxen.” Oxen did most of the hauling within the shipyard until 1898.5 Laborer Timothy Murphy was the shipyard’s designated bell ringer who signaled the beginning and end of the ten hour workday.

5. Carlson, Stephen P., Charlestown Navy Yard: Historic Resource Study, Volume 3, United States Department of the Interior, Washington, D.C., 2010), p. 11.

The day-to-day management and supervision of the shipyard civilian workforce relied on the master mechanics. They were the best paid and most important workmen. Each trade had a master mechanic, e.g., like master blacksmith Ebenezer Ford and master carpenter Nathaniel Crocker. These individuals were recognized experts in their specialty and each usually had many years of trade experience. The master mechanics often supervised large numbers of employees. Within each shop, it was a master mechanic who gave overall work direction. Master mechanics were formidable figures for they had the power to not only direct work but to hire and dismiss mechanics and laborers. Given the sheer size of the navy yard and number of carpenters, Nathaniel Croker exercised authority through three quartermen who directed several work crews. They were George Pook, quarterman of the carpenters on the wharf, James Maskell quarterman for carpenters on the ships and Samuel Roulstone, quarterman for carpenters working on the gun carriages. Next in the shipyard hierarchy was the lead man or small crew leader, then trade mechanics.

The term “mechanic” in the early nineteenth century referred to a skilled tradesman who had successfully completed a five or six year trade apprenticeship in a particular field. The Boston 1846 Employee List enumerated 13 apprentices and 11 young workers designated as “boy” on the list below. These boys were usually under the age of 16 and not part of a formal apprenticeship program. Each trade had such fully qualified or “journeyman” workers. Typically, these men were proficient with all the tools of their trade, having successfully completed their apprenticeship and had shown their tradecraft in a multitude of demanding work assignments. A journeymen wages depended on market conditions and scarcity. At the high-end, 1st class carpenters, mason’s blacksmiths and engineers earned $2.00 per day while apprentices were usually allowed to begin their training at about age 16 and would continue to work and learn under the tutelage of master mechanic until they had successfully completed their indenture. During this era, records reflect certain jobs became family affairs; nepotism, especially in the trades, was prevalent and it is common for the same surname to appear again and again.

The records of the Boston Navy Yard reflect that the preponderance of mechanics were able to read, write and use basic shop mathematics. Each master mechanic took on so many trainees. These apprentices were young workers in training. Each apprentice or parent/guardian signed a binding legal agreement, typically with a master mechanic, to return designated service in exchange for being taught his trade.

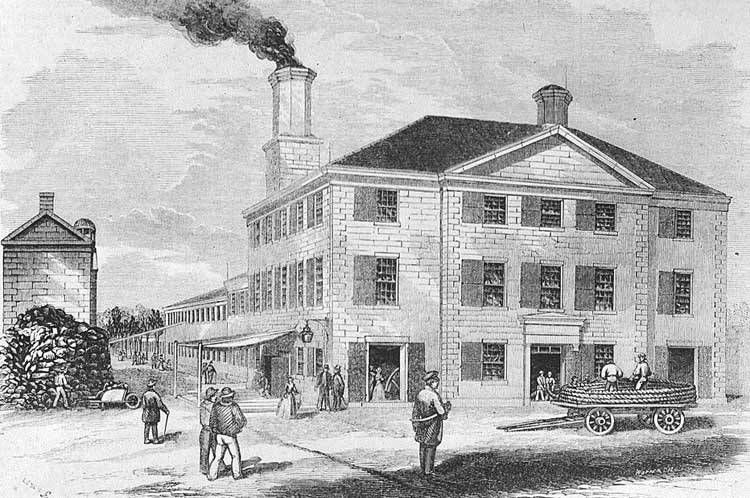

One distinctive feature of the Boston Navy Yard was the Ropewalk opened in 1838 which would continue to supply cordage to the U.S. Navy until 1975. One of the most important civilian positions at the Charlestown facility was the superintendent of the Ropewalk, William Caban, who was paid $4.00 per day. The whole complex was powered by massive steam engines and tended by men and boys. In the late winter of 1842-43, the new Tufts engine was purchased for installation in the Ropewalks head house. The Ropewalk had numerous unique jobs such as the spinner, who combined bundles of hemp fiber into bundles, and “heckler” where Charles Davis, John Aiken and John Cook sorted and prepared the hemp fibers, and tar house overseen by quarterman Samuel Miller. The tar produced by Miller and his crew was used to preserve and strengthen the rope and was also applied to canvas used on sails.

In the autumn of 1845, to protect the United States hemp production, Secretary of the Navy, Bancroft, ordered that in the future no foreign hemp would be received at the Ropewalk except when there was no domestic hemp on the market. To insure this directive was honored, the bureau had to certify annually that no domestic hemp of suitable quality was being offered for sale.6 On May 15 1846, Secretary of the Navy Bancroft authorized overtime for workers in the Ropewalk. However, no artificial lighting would be permitted in the building so that the extra work would have to be done during daylight hours which at that time of year stretched from 400 a.m. to 800 p.m.7

6. Ibid, p. 28.

7. Ibid, p. 59.

Laborers were below the mechanics. They were unskilled men who performed heavy but necessary work, such as stacking and retrieving timber, digging, pile driving and pulling or hauling of ships and ship parts. They were paid $1.00 per day. At Boston, the laborers typically carried material or supplies to tradesman, such as wood to the carpenters, mortar to the masons and helped clean the grounds.

Apprentices were generally age 16. When applying for the program, they had to show good character and the ability to read, write and do basic math. Nicholas Blaisdell as an apprentice boat builder, and Samuel H. Pook as an apprentice naval constructor, were trainees in highly skilled trades. Both of these young men worked for their fathers. The pay of an apprentice varied and was usually prorated based on the journey level wage rate of the trade and the age of the boy.8 In January 1846, there were about eighteen laborers on the shipyard work rolls. The shipyard could rapidly engage workmen during the peak spring and summer months.

8. Charlestown Navy Yard, Boston National Historical Park, National Park Service, Department of the Interior, Washington D.C., p. 18.

The life of most manual workers at Boston Navy Yard was governed by a few basic facts. First all workers, were in law, day laborers; that is they were paid a per diem wage only for days actually worked. As day labor these workers were in no positon to bargain. In the early nineteenth century employers almost everywhere in the new nation successfully challenged strikes and work stoppages in the courts. Strikes constituted illegal conspiracies in common law and exposed labor union members to criminal prosecution. Indeed, many individual states banned labor associations as "injurious to public morality or trade or commerce." Despite legal impediments, workers still struck employers. The ship caulkers had struck on 3 January 1835 and on Saturday August 1846 there occurred what was probably the second strike in the history of the Boston Navy Yard twenty workmen in the plumbers department walked off the job. In both instances the striking workers were summarily fired.9 The Civil Service or Pendleton Act of 1883 was still decades away and retirement for federal workers would only become law in 1920.

9. Frederic R. Black and Edwin C. Bearss Charlestown Navy Yard 18421890 (National Park Service, Washington, D.C., 1993), p. 46.

Like other American workers, Boston Navy Yard employees worked a six-day week and ten hour day, with no retirement or health care plans, still many were able to improve their lot. Workers lives though were often filled with hard and unpleasant uncertainties. In 1846 an injury or death at the shipyard meant no wages. Even for those who died on the job, their families received no compensation. For the Yard mechanics and laborers, a steady number of naval ships to build or overhaul was key to happiness and steady employment. Typically the supply of work followed the seasons with the Yard taking on more mechanics and laborers in the spring and summer months and the workers being laid off, especially laborers, in the fall and winter as the cold weather, rain and snowmade work in the open air impractical. More than skilled craftsmen, the laborer's job depended on the amount of work at the shipyard. Cold weather or the completion of an overhaul filled workers with anxiety. Most Yard laborers had little savings on which to fall back on and imprisonment for debt within the Boston community continued as a daily reality experienced by many workers each year. During theninetieth century, the Department of the Navy had no centralized records for its civilian employees. The Department, with rare exceptions, did not collect ethnic or racial information in any systematic wayon its military or civilians. The National Park Service historians who have reviewed the surviving records believe that at midcentury the records show most of the men were born in New England – half from Massachusetts. By 1850 some 15% of all employees were Irish, the majority of whom were working as laborers.10 In the 1840’s and 1850’s, nativistic stereotyping governed the composition of the labor force assembled to repair and build wharfs, many of which were damaged in storms. Because the Irish were believed to be better able to work in mud and water than native-born Americans, these recent immigrants were hired for this back-breaking toil.11 Locating records regarding the number of African American workers at the Navy Yard has proven difficult.

10. Ibid, p.18

11. Frederic R. Black and Edwin C. Bearss, Ibid, p. 22.

The early records of Boston Navy Yard documenting a civilian employees entrance on duty, rate of pay, etc., are scarce, consequently we are fortunate that the 1846 Employee List survived, for it now gives us our most extensive overview of the Boston Navy Yard and its employees at midcentury. As historian Gordon Wood has noted, such finds allow us the opportunity to “see the participants of the past in a comprehensive way in the context of their own time."12

12. Gordon S Wood, The Purpose of the Past Reflections on The Uses of History (Penguin Press New York 2008), p. 11.

Transcription: This transcription was made from the letter Parker to Bancroft, 6 January 1846, pp 1-11, Letters Received by the Secretary of the Navy from Captains (“Captains Letters”), Volume 326, 1 Jan 1846 to 31 Jan 1846, Letter Number 26, RG 260, National Archives and Records Administration, Washington D.C. In copying all passages from the letter and documents, I have striven to adhere as closely as possible to the original in spelling, capitalization, punctuation, and abbreviation, superscripts, etc., and underlining found in the original. The one notable exception for clarity and ease of retention: instead of using confusing “ditto” or “do” meaning “same thing again” (frequently used in Boston Navy Yard lists and accounts.), I have simply pasted in each employees full title, wage rate and description of duties and responsibilities. Words which are unreadable or illegible are so noted in square brackets. When a spelling is so unusual as tobe misleading or confusing, the correct spelling immediately follows in square brackets and italicized type or is discussed in a foot note. The names of naval ships, vessels and signatures are italicized.

John G. M. Sharp, 4 April 2022

* * * * * *

Navy Yard Boston

Commandants Office

6 January 1846Sir,

In obedience to the order of the Dept of the 29th ulto to furnish a completer list of all persons employed in this Yard with a statement of the salaries paid to, and particular duties performed by each, I herewith enclose a report of the same.

I have the honor to be Sir very respectfully

[Signed Foxhall H. Parker

Hon George Bancroft

Secretary of the Navy

Washington[End Page 1]

Navy Yard Boston

January 5th 1846Sir, In compliance with your order, I respectfully submit a list of all persons employed in this Yard on the 1st day of January 1846 with the salaries paid to, the particular duties performed by each.

I am very respectfully Sir, Your Obedient Servant

S. M. Pook, N.C

Commodore

F. H. Parker1313. Foxhall Alexander Parker Sr. (1788 to 23 November 1857) was an officer in the United States Navy. He was Commander-in-Chief of the East India Squadron (ie. U.S. Navy forces in the Far East), later commanded the Home Squadron, and was commander of the Constitution. He commanded the United States Navy Yard, an assignment he held for three and a half years.

Names of persons Samuel M. Pook14 Seth J. Thomas Thomas S. King William W. Pierce Edwin A. Hudleigh Matthew Rice Benjamin Hawkes Benjamin Crowninshield John Etheridge Daniel Henshaw Phillip Peckham Nicholas Blasidell Wm G. Clapp Nicholas Blaisdell Nathl Crocker George G. Pook James Merkell Samuel Roulstone Richd C. Bazen Joseph F. Dickinson John Smith Ambrose Jordon Henry A. Rice William W. Syles Edward Miskelly Guten Gardner Henry Conn Marvin Simmons Thomas Barker James Ferguson George W. Jordan Henry A. Davis Samuel Dinsmore Stephen C. Clarke Charles Rice William Farris George B. Preble Lenhil M. Phillips Samuel H. Pook John Perskins John Creighton Lawrence Bimerick Lutwick McLaughton Ebenr Bachette Asa Blachard Joshua W. Lincoln Thomas Felton Jer Buell Mark Durkins James Hobbs Asa Bird Patrick Green John Cassidy Francis Gallagher Luke Roach John Flannaghan Edward Conway William Quinn Edmund Conway Bernard Riley Aden Sampson Esra Brown Alexander Mc Farlane Alphesus W. Luke Augustus Whitmore Stephen F. Ladd Andrew Moulton Horatio N. McFarland David Simpson Benjamin E. Choate Jonah Libbey Moses W. Hawkes Joseph Porter S. A. Wright Ebenr Ford Wm McFarland John McCumber John Butler Jeremiah Preble Moses Richards Matthew Stanborn Sylvanias Daniels John Stetson Ebenr Averil Simon Seavey Charles Yeaton Joseph Stigers John Gibbs James Gardner Dannison McFarland Samuel Eastman William Grove William A Barnard Peter Mc Guin Francis Simmonds James Baning James Covey Samuel Champaney Charles Fulman Charles F. Carr James M. Coswell Thomas Bentley James Niles Caleb Hammett Wm M. Bechforf Antonio Rose Leonidas Wilson Abishai Cottle Hiram Wilig Henry Bridges Thomas M. Chandler Charles H. Wing Frederick Waller Wm Simpson George M. McFitch Patrick Kelling Phillip C. Revere Sargent O. Morse Henry P. Thayer Robert Torrence Emory Belcher Nelso Buchland T.S. Warner Henry M. Rose Edward CreightoN Cyrus Cobb Josiah C. Bradburg Samuel Woodbridge Henry Quincy Thomas Sargent Moses Seavey John Hurtling James Rose Jr. Charles Peirce Joseph Fernald Wm R. Moore John Mitchell James Reilly Caleb Green George W. Perkins John H. Scott John Barrell James Dearborn Henry Dana James Hayes E. S. Vaughan John Deaborn Artemas Chase Daniel Hopkins Patrick Hopkins Noah Butts Joseph G. Hicks John P.Marston James A. Porter John Crocker Joseph Welles Wm D. Butts Thos Brunnall Phillip Hitchborn A. L.Melvin Danl B. Gardner James Rose Jacob Farnsworth Benjn F. Hawkes Arthur McGuire James Overn Jeremiah Ryan Felix McGuire Gilbert Colburn Francis Powers James McNamara James Harrington Daniel McCarty Edward Welch Richard Follens Dennis Ryan Daniel Shehan Maurice Donnighan John Mannix John Buteman Martin Tapiscoli Luke Hurley John Williams Artemas Sylvester Robert Danvir Thomas Hewett Thomas Murphy Timothy Murphy Constantine Tenechic Edward Powers Michael Carroll Richard Welch Dennis Sullivan John Ryan Edward Quinlan Wm McKean Daniel Dooley Frank Murphy Michael Doyle William Dwyer Maurice Drinnin Patrick Murphy Eugene Mack Henry Mountain Robert Peppard John Harrington Pater McArdle Daniel Murphy Augustus Taylor Frederick G. Smith John Boyde Edward Mc Brady James Loman John Wright Patrick Sullivan Cornelius Sullivan George Wilson John Kegan Morris Monroe James Wiley Michael Bright Levi Locke Jonathan Calley Cyrus Blanchard Joseph F. Boyd Simon Lamprell George H. Clapp Wm D. Hills John Gabriell Thomas Lyons Wm M. Howells Washington Armstrong John Wills John Berry John Stills John T. Boyd Edward Harding Aron Hadely Jr. Galen J. Gardner Joseph Loring Edward Enslin Warren Barnard William Caban Wm Patrick Saml Pearsen Samuel Miller Francis H. Joy Thomas M. Melvin William Lund Charles Lang Wm G. Plummer Joseph Patrick Joseph Bibrum Daniel Cardwell Wm McCloud George Pearson Stephen H. Clarrage Stephen Luiner James Mahoney Thomas H. Green James S. Qwinn Edward Butler Horace H. Matson Thomas Taylor John Laskey John Childs James Noyes Robert Reeves Herbert Garden Saml Williams Michael Noyes Henry P. Gardner Abram Noyes [Illegible] Richardson Charles Davis Thomas Doherty John Low John H. Robbins Mark Moren John Aiken John Cook Royal Underwood J. L. Robbins George Scott George Richardson Louis Boudel Michael Keely Jr John Silva Stephen Fosdick Aron Mason Peter Henneman John Miller Daniel Fosdick Henry Lewis Edward B. Hart Robert Sutton John Wilson Ralph Taylor Maurice Flynn 14. Samuel Moore Pook (August 15, 1804 – December 2, 1878) was a Boston-based American naval architect and father of Samuel Hartt Pook, the noted clipper ship naval architect. In 1861, at the outbreak of the American Civil War, Pook designed the City class ironclads for James B. Eads. The City class ironclads, also known as "Pook Turtles" due to their distinctive shape, were the backbone of the naval flotilla deployed by the United States Navy on the Mississippi River System during the American Civil War.

15. Heckling (or "hackling") is the last of three steps in dressing flax, or preparing the fibers to be spun. It splits and straightens the flax fibers, as well as removes the fibrous core and impurities. Flax is pulled through heckling combs, which parts the locked fibers and makes them straight, clean, and ready to spin. After heckling and spinning, flax is ready to be woven into linen.Hood, Adrienne D., The Weaver's Craft: Cloth, Commerce, and Industry in Early Pennsylvania, (University of Pennsylvania Press, Philadelphia, 2003.

* * * * * *

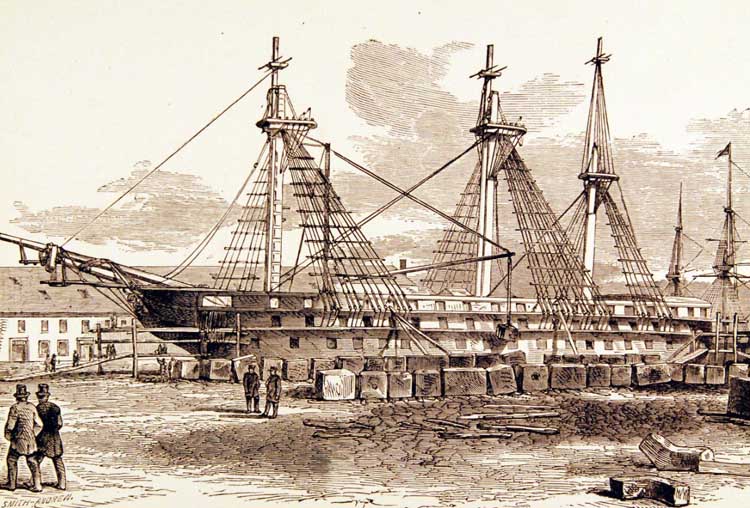

Vintage Illustrations of Boston Navy Yard (public domain)

1. 1833 Boston Navy Yard, view of one of the Wharfs by William Bennett 1833,

2. USS Vermont, Ship of the Line 1850's in Dry Dock number 1, Boston Navy Yard

3. Boston, Charlestown Navy Yard Ropewalk, 1852

4. Boston Navy Yard, Receiving Ship Ohio about 1860* * * * * *

John G. "Jack" Sharp resides in Concord, California. He worked for the United States Navy for thirty years as a civilian personnel officer. Among his many assignments were positions in Berlin, Germany, where in 1989 he was in East Berlin, the day the infamous wall was opened. He later served as Human Resources Officer, South West Asia (Bahrain). He returned to the United States in 2001 and was on duty at the Naval District of Washington on 9/11. He has a lifelong interest in history and has written extensively on the Washington, Norfolk, and Pensacola Navy Yards, labor history and the history of African Americans. His previous books include African Americans in Slavery and Freedom on the Washington Navy Yard 1799 -1865, Morgan Hannah Press 2011. History of the Washington Navy Yard Civilian Workforce 1799-1962, 2004.

https://www.history.navy.mil/content/dam/nhhc/browse-by-topic/heritage/washington-navy-yard/pdfs/WNY_History.pdf

and the first complete transcription of the Diary of Michael Shiner Relating to the History of the Washington Navy Yard 1813-1869, 2007/2015 online:

https://www.history.navy.mil/research/library/online-reading-room/title-list-alphabetically/d/diary-of-michael-shiner.html

His most recent work includes Register of Patients at Naval Hospital Washington DC 1814 With The Names of American Wounded From The Battle of Bladensburg 2018,

https://www.history.navy.mil/research/library/online-reading-room/title-list-alphabetically/r/register-patients-naval-hospital-washington-dc-1814.html

The last three works were all published by the Naval History and Heritage Command. John served on active duty in the United States Navy, including Viet Nam service. He received his BA and MA in History from San Francisco State University. He can be reached at sharpjg@yahoo.com